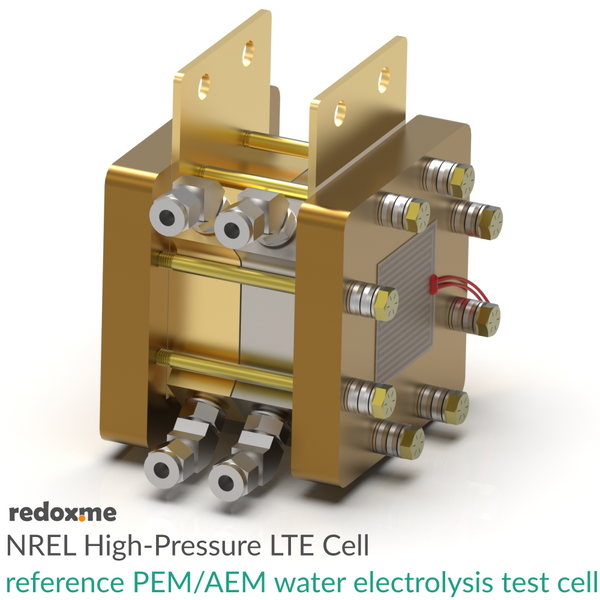

NREL High-Pressure LTE Cell - NREL High-Pressure Low-Temperature Electrolysis Cell

Developed by National Renewable Energy Laboratory (NREL) High-Pressure Low-Temperature Electrolysis (LTE) Cell is on open-source cell hardware designed for repeated reassembly. This work was planned and funded by the U.S. Department of Energy’s H2NEW consortium.

Redox.me offers a 25 cm² PEM variant produced based on the technical documentation from NREL, as well as other variants developed by redox.me according to NREL guidelines. In the former, the flow field pattern is directly translated from 25 cm² PEM variant. The dissemination of these products aims to facilitate easy access to this equipment for a wide range of users. However, if you have the capability to produce the 25 cm² PEM variant on your own, we encourage you to use the open-source files. It may turn out that if you have access to your own technical resources, this will be a more cost-effective option. 3D CAD models and 2D technical drawings for variant 25 cm² PEM are available for download.

High pressure LTE operation can reduce operating costs, as it is more efficient to produce electrochemically pressurized hydrogen compared to using downstream mechanical compressors. However, the cell is also compatible with ambient pressure LTE.

The cell can accommodate porous transport layers of varying thicknesses. To achieve this, the number of gaskets on each side of the cell can be increased, providing a larger volume for the porous transport layer.

One benefit of the smaller surface area variants (1 cm² and 4 cm²) is their compatibility for testing with a potentiostat and booster. In these cases, the current levels are typically within the acceptable range for most boosters. However, for larger active surfaces with current densities up to 6 A/cm², a high-power programmable DC power supply may be required.

Application note

The documents and drawings linked below outline the design of low-temperature electrolysis hardware that is intended to meet leak testing standards as per ASME B31.1. They also provide comprehensive cell assembly instructions and a procedure for performance benchmarking. The responsibility for safe operation at both ambient and elevated pressures lies solely with the end user, and each individual cell should be assessed on a case-by-case basis. The sealing effectiveness may be influenced by factors such as machining quality, components used in cell assembly, operating conditions, and the operational history. Pressure operations should only be conducted on qualified test stands by trained operators.

Wrubel, Jacob, Samantha Ware, Corey Schaffer, Matt Allen, Ellis Klein, Robin Rice, Chaiwat Engtrakul, and Guido Bender. 2023. "NREL 25-cm2 High-Pressure Low-Temperature Electrolysis Cell Hardware (Open Source)." NREL Data Catalog. Golden, CO: National Renewable Energy Laboratory. https://doi.org/10.7799/2205626

Specification

cell

active area: 25 cm², 4 cm² or 1 cm² (other on request)

maximum verified working pressure: 30 bar

flow field design: triple serpentine (other on request)

temperature sensor

sensor type: Pt100 x2 (100 W at 0 ºC)

construction: Wire-Wound, 10 mm tails

fundamental interval: 38.5 W (nominal)

self-heating: 0.02 to 0.3 ºC/mW

thermal response: <0.4 s

measuring current: 1 mA

diameter: 1.5 mm

length: 15 mm

tolerance class (IEC 60751): Class A

temperature range: -200 ºC to +650 ºC

body material: alumina

adhesive-backed pad heater

power source: electric

voltage: max 60 V

power: max 59 W

resistance: 61 W

material: polyimide

maximum temperature: 250 ºC

wire type: silicone braided wire

insulating resistance: >5 MW

size: 50 mm x 50 mm

thickness: <0.266 mm

adhesive: 3M

wire length: 60 mm

fittings

body material: Stainless Steel 316

connection 1 size: 1/4 in. tube OD (6.35 mm)

connection 1 type: Swagelok® Tube Fitting

connection 2 size: 7/16-20 in.

connection 2 type: male SAE/MS straight thread

reference: Swagelok® part #: SS-400-5-4ST

Intrastat data

HS Code: 90278080

Country of Origin: Sweden

NET weight: 2000 g

List of Materials

anode flow field (PEM): platinum coated titanium (grade II)

cathode flow field (PEM): gold coated titanium (grade II)

anode flow field (AEM): pure nickel

cathode flow field (AEM): pure nickel

threaded end plate: anodized aluminium

unthreaded end plate: anodized aluminium

current collectors: gold coated (nickel interlayer) copper (101)

fittings: Stainless Steel 316

bolts: zinc yellow-chromate plated steel grade 8

gaskets: skived PTFE and FKM

washers: Stainless Steel18/8

Belleville washers: Stainless Steel 302

insulating tape: PEEK

alignment pins: PFA

temperature sensor body: alumina

adhesive backed pad heater: polyimide with 3M adhesive

Setup includes

1 x anode flow field

1 x cathode flow field

1 x threaded end plate

1 x unthreaded end plate

2 x current collector

4 x Swagelok® part #: SS-400-5-4ST fitting

8 x bolt

10 x FKM gasket

10 x skived PTFE gasket

16 x washer

64 x Belleville washer

2 x insulating PEEK tape

4 x alignment pin 11 mm long, 3 mm OD

2 x alignment pin 8 mm long, 3 mm OD

2 x dual Pt100 temperature sensor

2 x adhesive backed pad heater

Related products

Modular PEM Electrolyzer Test Station