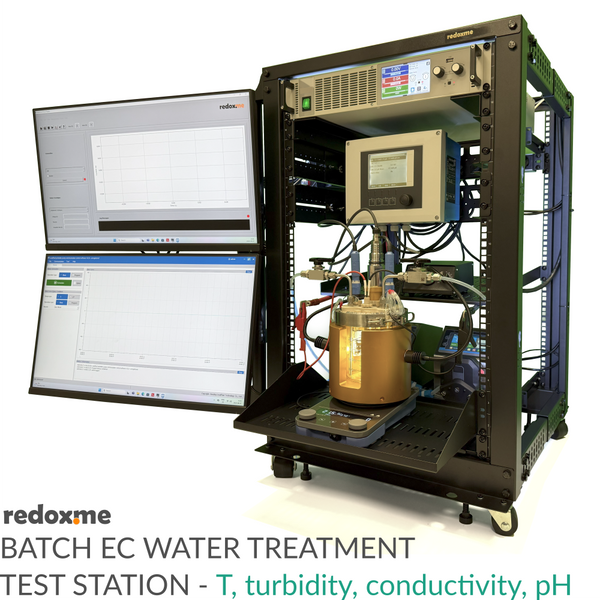

Batch Electrochemical Water Treatment Test Station

The Batch Electrochemical Water Treatment Test Station is a versatile laboratory platform designed for the investigation and development of a wide range of electrochemical water treatment processes. Operating in batch mode, this test station allows precise control over experimental conditions, including current, voltage, temperature, and mixing, making it ideal for both research and process optimization.

Its modular design supports multiple electrochemical treatment methods, including:

a) Electrochemical coagulation for the removal of suspended solids, metals, and phosphates.

b) Electrochemical oxidation for the degradation of organic contaminants and advanced oxidation processes (AOPs).

c) Electrochemical reduction for the treatment of specific pollutants, such as nitrate or hexavalent chromium.

d) Electroflotation to assist in the separation of flocs and colloids.

e) Electrochemical disinfection through in-situ generation of reactive species.

This test station is suitable for fundamental studies, method development, and pilot-scale experiments, providing researchers and engineers with a flexible and reliable tool to explore, optimize, and scale electrochemical water treatment technologies. Its batch operation ensures easy sampling, monitoring, and adjustment of reaction parameters, enabling thorough analysis of reaction mechanisms and process efficiency.

This Batch Electrochemical Water Treatment Test Station comes, in its standard configuration, equipped with turbidity, pH, temperature, and conductivity sensors, providing real-time monitoring of key water quality parameters. Additional sensors can also be installed upon request, allowing full customization to meet specific experimental needs. This includes chemical sensors (oxidation-reduction potential, dissolved oxygen, free chlorine/chlorine dioxide, hydrogen peroxide, ammonia/nitrite/nitrate, total organic carbon, and metal ion sensors), physical sensors (pressure, flow, optical/UV absorbance, particle size), and reference electrodes.

Programmable DC Power Supply is powered by a single-phase voltage, offering an output voltage of 0-60 V, current of 0-120 A, providing up to 3 kW of power. It seems obvious that the power offered by this power supply far exceeds the practical requirements of a 1 L batch reactor. However, its use is justified by the possibility of system expansion and performing reactions on larger electrode surfaces or in a flow cell with a stack configuration. Thanks to the use of proprietary software developed by redox.me, it is possible to measure parameters in real-time using a computer. Other system components, such as the cell, electrode holders, and additional elements, can also be customized upon request.

Application note

The Batch Electrochemical Water Treatment Test Station is ideal for:

a) Laboratory research and fundamental studies of electrochemical processes.

b) Development and optimization of new water treatment methods.

c) Pilot-scale testing before scale-up to continuous-flow systems.

d) Investigation of reaction kinetics, efficiency, and mechanisms in controlled batch conditions.

Main benefits include: high experimental flexibility and customization, real-time monitoring of multiple water quality parameters, support for a broad range of electrochemical water treatment processes, detailed analysis of process performance, efficiency, and scalability.

This is the list of electrode materials typically used in a Batch Electrochemical Water Treatment Test Station, organized by type and common applications:

1. Anode Materials (for oxidation reactions)

- Boron-Doped Diamond (BDD) – very high oxidative power; used for degrading organic pollutants, generating hydroxyl radicals.

- Dimensionally Stable Anodes (DSA, e.g., Ti/IrO₂, Ti/RuO₂) – widely used for electrochemical oxidation, chlorine generation, and disinfection.

- Platinum (Pt) – strong oxidation, often for small-scale lab experiments; expensive but highly stable.

- Mixed Metal Oxides (MMO, e.g., Ti/Ta₂O₅-RuO₂, Ti/IrO₂-RuO₂) – good stability and moderate cost; used in both oxidation and chlorine generation.

- Graphite / Carbon-based electrodes (Carbon Felt, Carbon Cloth, Graphite Plate) – good for organic oxidation, cost-effective, often combined with electrochemical reactors for research.

2. Cathode Materials (for reduction reactions)

- Stainless Steel (SS) – widely used, cost-effective, good for general electrochemical reduction.

- Platinum (Pt) – highly active for hydrogen evolution and reduction reactions.

- Nickel (Ni) – good for hydrogen evolution and reduction of nitrates.

- Carbon-based cathodes (Carbon Felt, Graphite) – inexpensive, large surface area; used in batch experiments for electro-reduction processes.

3. Specialized / Research Electrodes

- Mixed metal oxide cathodes – for specific electrochemical reactions.

- Ti-based cathodes with coatings (Ti/Pt, Ti/Ni) – for corrosion resistance in aggressive solutions.

- 3D porous electrodes (Carbon Foam, Reticulated Vitreous Carbon) – for enhanced mass transfer and high surface area.

The Batch Electrochemical Water Treatment Test Station is continuously being improved, so the photos may not fully represent the current version of the device.

Specification

weight: 100 kg

height: 98 cm (18U)

width: 126 cm (75 cm with folded monitors)

depth: 94 cm

default sensors: turbidity, pH, T, and conductivity

default electrochemical cell volume: 1 L

recommended electrode size: 50 mm x 50 mm

maximum electrode size: 80 mm x 50 mm

monitor size: 27 inches each

monitor type: Lenovo ThinkVision

PC type: Lenovo ThinkCentre M70q

pump type: high-performance peristaltic

tubing size: 1/4'' (6.35 mm) OD

tubing materiał: Stainless Steel and FEP

lightning: 6 W double gooseneck LED illumination and two 5 W LED strips

internal power rail: 16 CEE7/3 electrical sockets

maximum input power: 3 kW

maximum input current: 120 A

maximum input volatge: 60 V

power connection: 230V, 3 kW, single phase

Intrastat data

HS Code: 85433000

Country of Origin: Sweden

NET weight: 100 kg

Setup includes

1 x 19-inch rack (18U), with shelves, rails, and holders

2 x power rail, 8 CEE7/3 electrical sockets

2 x 5W LED stripe

1 x 24W, 24V LED power supply

1 x 6W double gooseneck LED illumination

1 x digital hot plate/stirrer, 130 mm dia.

2 x peristaltic pump

1 x 4-channel transmitter

1 x pH sensor

1 x conductivity/temperature sensor

1 x turbidity sensor

2 x power cable for electrode

1 x dry heat block

1 x electrochemical cell

1 x adjustable dual-electrode holder

1 x progammable DC power supply, 60V, 120A, 3kW

1 x redoxmePS software installation pack for programmable DC power supply

1 x PC Lenovo ThinkCentre M70q

2 x 27-inch Lenovo ThinkVision monitor

1 x USB-C docking station

1 x set of electrical connection cables (installed)

1 x set of tubbing (installed)

Related products

reference electrodes

working electrodes and current collectors

metal auxiliary electrodes