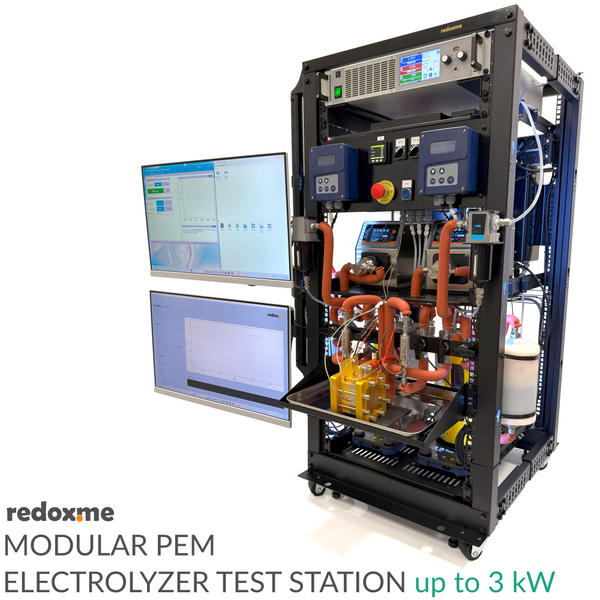

Modular PEM Electrolyzer Test Station up to 3 kW

The Modular PEM Electrolyzer Test Station is a versatile and flexible solution designed for the testing and evaluation of proton exchange membrane (PEM) electrolyzers. Unlike fully automated, integrated systems, this platform features modular components that can be easily swapped by the end user, allowing for customized setups and adaptability to different testing needs. The platform is engineered to provide precise control and measurement of electrochemical performance while offering the convenience of easily replaceable parts. This design enables users to test various configurations, integrate new modules, and adapt the system to specific research or development objectives without the need for specialized equipment or extensive downtime. Ideal for research labs and development environments, this platform supports the advancement of PEM electrolyzer technology through hands-on, flexible experimentation.

The Modular PEM Electrolyzer Test Station can be ordered as a complete system including Modules 1, 2, 3, 4, and 5. In that case, we will deliver a tested system ready for operation. You can also choose individual modules if you only need them for your own setup. If you need any customization for any of the modules, let us know.

The Modular PEM Electrolyzer Test Station consists of several key modules, each designed to provide flexibility and precision for various testing scenarios:

1. Enclosure and Electrical Installation Module - This module consists of a metal housing in the form of a 19-inch server rack, 25 units high, with additional rails and shelves. The rack does not have panels, so its structure is open on all sides. Only the electrical components are housed in specially designed boxes (front and rear). The module includes two 230V power rails with a total of 16 CEE7/3 electrical sockets. The module has its own LED lighting to facilitate work with system components that have their own consoles. Mounted on the left side of the rack is a holder for two monitors up to 27 inches in size, and a mount for a Tiny Form Factor computer with VESA mount. Monitors and the computer are not included with this module. The module is equipped with electrical safety circuits in the form of differential cut-off, an emergency button, a reset system, and additional circuit switches. It is powered by single-phase 230 volts, 16A, 3.7 kW. This module is delivered in an assembled form, ready to be integrated with other modules.

2. Electrolyte Supply Module - This module manages the supply of deionized water or electrolytes to the electrolyzer. This module consists of two symmetrical liquid circulation systems. Each system includes a hermetically sealed tank for water/electrolyte (3L glass jar with a PEEK lid sealed with a double FKM O-ring and secured with a stainless steel clamp), a gear pump (with a PEEK head) controlled from the pump panel or computer (software included, PC is not included in this module), an ion exchanger (with operating temperature up to 200 °F, 93 °C) with a ball valve, a conductivity and temperature sensor with a T-shaped metal enclosure, a digital sensor reader, and a set of Swagelok fittings and accessories. Additionally, a stainless steel drip tray and a rubber mat are included, on which the electrolyzer can be placed and secured in case of any fluid leakage. If you order only this module, it will be delivered as unassembled components. Tubing is not included in the set. This module does not include components allowing for operation under elevated pressure. However, thanks to the use of Swagelok fittings, you can expand the system to include this functionality yourself.

3. Temperature and Heat Management Module - This module monitors and controls the temperature of the electrolyzer system. It consists of two symmetrical heating systems. Each system includes a digital hotplate (130 mm diameter, built-in magnetic stirrer), an inline heater (500 W power, 240 V, 210 W/in², 250°C max temperature), a PID controller (two channels, controlled from the panel or computer), a Pt100 temperature sensor (stainless steel body, 3 mm diameter, 25 mm long) to be installed in the electrolyzer, a solid-state relay, a dry heat block (thermally isolated anodized aluminum), a DC power supply (24 V), and a thermal insulation set for self-installation. If you order only this module, it will be delivered as unassembled components.

4. Gas Flow Module - This module is designed to manage and control the flow of hydrogen and oxygen gases generated by the electrolyzer. It consists of two symmetrical circuits, with the only difference being the type of sensor installed. Each circuit includes a phase separator that separates gas from liquid, a back pressure regulator with an analog pressure gauge, and a safety gas sensor system. Each sensor is connected to the circuit using a T-shaped enclosure made of PEEK. In the cathode circuit producing hydrogen, an oxygen sensor is placed (linear, 0.10 ± 0.03 mA output signal, 0-25 % oxygen measurement range, 800-1200 mbar pressure range, 5-95% RH operating humidity range). In the anode circuit producing oxygen, a hydrogen sensor is placed (linear, 10 ± 5 nA/ppm output signal, 0-5000 ppm hydrogen measurement range, 800-1200 mbar pressure range, 15-90 % RH operating humidity range). The signal from each sensor is read using an OEM version of a potentiostat with a USB connection. With the attached software, it is possible to monitor gas concentration using a computer which is not included with this module. If you order only this module, it will be delivered as unassembled components.

5. Measurement and Data Acquisition Module - This is a critical module of the system that controls the operation of the electrolyzer and monitors and records its performance indicators. The main component of the module is a Programmable DC Power Supply with connection cables. It is powered by a single-phase voltage, offering an output voltage of 0-60 V, current of 0-120 A, providing up to 3 kW of power. Thanks to the use of proprietary software developed by redox.me, it is possible to measure parameters in real-time using a computer (Lenovo ThinkCentre M70q), which is part of this module. Additionally, the module includes two monitors (Lenovo ThinkVision, 27 inches), along with a docking station, keyboard, and mouse. If you order only this module, it will be delivered as unassembled components. Note that this module, as well as any of the others, does not include equipment for performing electrochemical impedance spectroscopy measurements (EIS). If this is necessary, you will need to purchase an EIS analyzer directly from your chosen supplier.

The electrolyzer is not part of the set, and if there is such a need, it should be added to the quotation separately.

Application note

Ideal for researchers investigating new PEM materials, flow field designs, and cell configurations. The system is an excellent tool for academic institutions and training centers, providing students and researchers with a hands-on understanding of PEM electrolysis processes and system operation. PEM Electrolyzer Test Station with power up to 3 kW is suitable for testing lab-scale or small to medium-scale electrolyzers, typically up to 60 cm². If the power requirements for a given electrolyzer are less than 2 A/cm², larger electrolyzers up to 100 cm² or more can also be tested.

The entire system, as well as its component parts, are CE certified, which signifies that a product meets European Union (EU) health, safety, and environmental protection standards. Other certificates are available upon request.

The Modular PEM Electrolyzer Test Station is continuously being improved, so the photos may not fully represent the current version of the device.

Specification

weight: 150 kg

height: 129 cm (25U)

width: 135 cm (85 cm with folded monitors)

depth: 90 cm

maximum input power: 3 kW

maximum input current: 120 A

maximum input volatge: 60 V

power connection: 230V, 3 kW, single phase

Intrastat data

HS Code: 85433000

Country of Origin: Sweden

NET weight: 150 kg

Setup includes

1 x Modular PEM Electrolyzer Test Station or selected module(s)

Related products

NREL High-Pressure LTE Cell - NREL High-Pressure Low-Temperature Electrolysis Cell