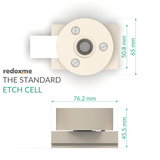

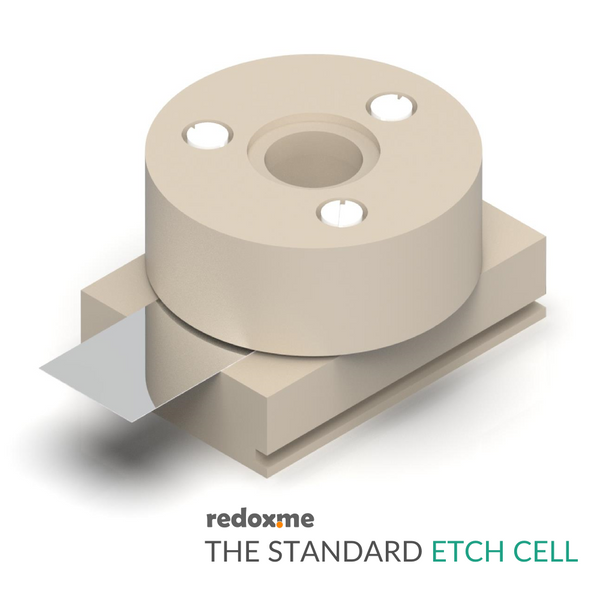

The Standard Etch Cell

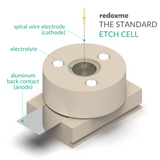

One of the most common applications of an electrochemical etching cell is the preparation of a Nanocrystalline Porous Silicon Layer on a single crystal Si wafer.

Application note

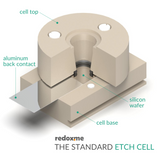

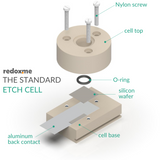

To perform an electrochemical process, a square conducting sample is placed on the cell base, using a piece of aluminum foil as a back contact. The setup is sealed by an O-ring to prevent electrolyte leakage. The cell is filled with an electrolyte, and the wire electrode is immersed in the solution as a counter electrode. An electric current is passed between the aluminum back contact and the wire electrode for a certain amount of time. After the process, the cell elements should be washed several times with ethanol and dried under the nitrogen flow. See the assembly demonstration here.

Specification

nominal exposure area: 1.20 cm2

electrolyte volume: 4.8 mL

minimum sample size: 20 mm x 20 mm

maximum sample width: 31 mm

Intrastat data

HS Code: 85433070

Country of Origin: Sweden

NET weight: 200 g

Product includes

1 x cell base - 0058CPEMASM

1 x cell top - 0060CPEMASM

1 x set of screws - 0057PNYCM

Related products

Spiral Metal Wire Electrode for Etch Cell

Glassy (vitreous) carbon substrates – GC 25/25/custom

This etch cell has been developed based on a design of Prof. Dr. Michael J. Sailor, published in Porous Silicon in Practice: Preparation, Characterization and Applications, Appendix A1. Etch Cell Engineering Diagrams and Schematics.