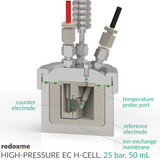

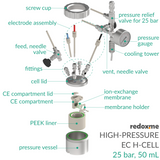

High-Pressure EC H-Cell, 25 bar, 50 mL - High-Pressure Electrochemical H-Cell

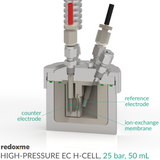

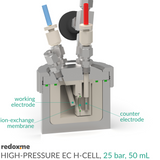

The High-Pressure Electrochemical H-Cell is a sophisticated apparatus engineered to facilitate advanced research in electrochemistry under elevated pressure and temperature conditions. In this cell separating the working electrode from the counter electrode with an ion-exchange membrane offers several advantages:

1. Prevention of Cross-Contamination: High pressure can exacerbate the diffusion of reactants and products between the electrodes. Using an ion-exchange membrane helps to prevent cross-contamination between the two compartments by selectively allowing ions to pass through while blocking the passage of larger molecules and particles. This maintains the integrity of the electrochemical reactions occurring at each electrode.

2. Control of Reaction Pathways: Different electrochemical reactions may occur at the working and counter electrodes. By separating them with an ion-exchange membrane, you can control the reaction pathways more precisely. This separation allows for independent optimization of reaction conditions at each electrode, such as pH or concentration gradients, leading to enhanced efficiency and selectivity of the overall electrochemical process.

3. Minimization of Side Reactions: High-pressure conditions can sometimes promote unwanted side reactions, which can decrease the efficiency of the electrochemical cell. By isolating the working electrode from the counter electrode with a membrane, you can minimize the occurrence of these side reactions by controlling the environment and reactant availability at each electrode separately.

4. Enhanced Stability and Durability: The ion-exchange membrane acts as a physical barrier that helps to stabilize the electrochemical cell under high-pressure conditions. It prevents direct contact between the electrodes, reducing the likelihood of short circuits, corrosion, or other forms of degradation that can compromise the performance and longevity of the cell.

5. Flexibility in Electrolyte Selection: Separating the electrodes with a membrane allows for the use of different electrolytes in each compartment. This flexibility enables the optimization of electrolyte compositions and properties for specific electrochemical reactions, leading to improved overall performance and compatibility with high-pressure conditions.

Overall, the use of an ion-exchange membrane to separate the working electrode from the counter electrode in a high-pressure electrochemical cell provides greater control, stability, and efficiency, ultimately enhancing the performance and reliability of the cell for various applications.

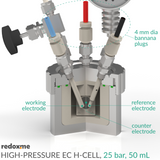

The cell is capable of withstanding pressures up to 25 bar and temperatures up to 200 ⁰C, allowing researchers to investigate electrochemical processes under hydrothermal conditions or using a hot pressurized environment for organic solvents as reaction media. It is a double-compartment cell that accommodates various electrode setups, including standard 2- or 3-electrode configurations and custom arrangements tailored to specific experimental requirements. The cell is designed to accommodate various electrodes and sample types, including solids, liquids, and gases, enabling comprehensive studies across different material systems.

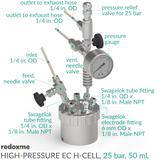

The cell is constructed from high-quality materials such as Stainless Steel 316L (outer body), PEEK (liner), and FKM elastomer (O-rings), ensuring robustness and reliability even under harsh experimental conditions. Cell material system is compatible with the following material systems: aqueous electrolytes in a full pH range, organic solvents (sulfoxides, amides, ethers, alcohols, aromatic), organic and inorganic salts (including fluorinated anions, ammonium), gases (N2, Ar, H2) – PEEK, FKM O-Rings. The cell is equipped with four 6 mm dia. electrode ports, two 1/4 in. OD tube gas/liquid inlet/outlet, and assembly of a manometer and safety relief valve (25 bar) mounted on the cooling tower. Additionally, there is a 1/8 in. OD port for a temperature probe inside the PEEK liner. The cell is compatible with the high-pressure working electrode, high-pressure counter electrode, and high-pressure reference electrode. Unused electrode ports can be terminated with high-pressure plug.

Application note

Catalysis plays a pivotal role in various industrial processes, from petroleum refining to pharmaceutical synthesis. Understanding catalytic mechanisms under realistic conditions is crucial for optimizing catalyst performance and developing efficient processes. The High Pressure Electrochemical Cell offers a sophisticated platform for studying catalytic reactions under elevated pressure and electrochemical environments simultaneously. The cell is typically used to investigate the effect of pressure on electrochemical kinetics and mechanisms, study the electrochemical behavior of materials under high-pressure conditions for applications in energy storage, catalysis, and corrosion, and explore novel electrode materials and electrolyte systems tailored for high-pressure electrochemical devices.

Electrodes are not included in the cell and should be added to the quotation separately.

Specification

maximum operating pressure: 25 bar

total volume of PEEK liner: 20 mL (CE) + 30 mL (WE)

recommended volume of liquid: 15 mL (CE) - 20 mL (WE)

maximum operating temperature: 200 ⁰C

port for temperature probe: 1/8 in. (3.175 mm)

electrode port diameter: 6 mm

number of electrode ports: 4

other port diameters: 1/4 in. (6.35 mm)

pressure gauge dial range: 0 - 40 bar

recommended tubing: 1/4 in. OD, 1/8 in. ID PEEK tube

Intrastat data

HS Code: 90309000

Country of Origin: Sweden

NET weight: 2500g

Safety note

The use of a High-Pressure Electrochemical H-Cell involves working with equipment capable of withstanding elevated pressures and conducting experiments with potentially reactive chemicals. Ensuring safety during operation is paramount to prevent accidents and protect personnel and equipment. Below are key safety considerations to observe when using the High-Pressure Electrochemical H-Cell:

1. Prior to operation, all personnel involved should receive comprehensive training on the setup, operation, and safety protocols associated with the High-Pressure Electrochemical H-Cell. Only trained individuals familiar with the equipment should be permitted to operate it.

2. Adhere strictly to the specified pressure limitations of the High-Pressure Electrochemical H-Cell. Do not exceed the recommended pressure range to prevent over-pressurization, which could lead to equipment failure and potential hazards.

3. Ensure that all materials, including electrodes, seals, and electrolytes, are compatible with the pressure and chemical environment inside the cell. Incompatibilities could result in leaks, corrosion, or other safety hazards.

4. Verify that the pressure relief mechanism is in place and functioning correctly. This mechanism is crucial for safely releasing excess pressure in the event of over-pressurization.

5. Regularly inspect the seals and connections of the High-Pressure Electrochemical H-Cell for signs of wear, damage, or leaks. Replace any compromised components promptly to maintain sealing integrity and prevent pressure-related accidents.

6. Establish clear emergency procedures, including evacuation routes and protocols for handling pressure-related incidents. Ensure that all personnel are aware of these procedures and know how to respond effectively in case of emergencies.

7. Wear appropriate Personal Protective Equipment (PPE), including safety glasses, gloves, and lab coats, when operating the High Pressure Electrochemical Cell. Additional PPE may be necessary depending on the specific experimental conditions and hazards involved.

8. Supervise experiments closely and monitor the High-Pressure Electrochemical H-Cell continuously during operation. Respond promptly to any abnormalities or unexpected changes in pressure or performance.

By adhering to these safety guidelines and exercising caution and diligence, users can minimize risks and ensure the safe and effective operation of the High-Pressure Electrochemical H-Cell in the laboratory. Always prioritize safety to protect yourself, your colleagues, and the integrity of the experimental setup.

Product includes

1 x pressure vessel, SS 316L

1 x PEEK liner 50 mL

1 x PEEK CE compartment

1 x PEEK CE compartment lid

1 x set of PEEK screws

1 x cell lid, SS 316L

2 x screw cup, SS 316L

1 x cooling tower, SS 316L

1 x manometer (0 – 40 bar)

1 x safety relief valve set for 25 bar

1 x 4-way union, Swagelok 1/4 in. OD, SS 316L

4 x electrode fitting, Swagelok 6 mm OD x 1/8 in. Male NPT, SS 316L

2 x fitting, Swagelok 1/4 in. OD x 1/8 in. Male NPT, SS 316L

2 x needle valve, Swagelok 1/4 in. OD, SS 316L

1 x set of O-rings, FKM,

1 x temperature probe fitting, IDEX, 1/8 in. x 1/4-28, SS 316L

3 x connecting unit, 1/4 in. OD, 1/8 in. ID, 30 mm long, SS 316L

2 x C-spanner 85 mm (cell opening tool)

1 x PEEK plug, 6 mm dia.

1 x PTFE tape

Related products

High-pressure working electrode

High-pressure counter electrode

High-pressure reference electrode

High-pressure plug